Thermoformed Pulp Processing

Iyo mold midziyo yeZhiben inoumbwa neSwitzerland HSM, WEDM, michina yekunyora, CMM, 26 muchina maturusi, nokudaro kufambisa kubudirira kwe "0.1μ feed, 1μ kucheka, nm-level surface effect".

Thermoformed Pulp Processing

Zhiben akatsvaga uye akagadzira yakazara otomatiki yakazara pulp molding michina (Pulp Machine / bepa pulp Machina).Nekushandiswa kwesimba kwakaderera uye maawa akawanda ekushanda sehwaro.Isu takapedza yedu nyowani pulp molding michina ine yakanyanya kureba isina kunyorwa maawa ekushanda.

Kugadzirwa kwe pulp yakaumbwa kunosanganisira kuturika kwemvura kwemafibhi achiiswa pane yakavharwa mold.Vacuum inozoiswa uye iyo fiber-mat inotanga kukudziridza rimwe simba.Mvura inogona kubviswa nekumanikidzika kunoshandiswa kune slurry nenzira yekufananidza mold.Mushure mechikamu ichi, preform yakaumbwa inowanzosvika 50% mukuenderana (kureva chidimbu chehuwandu kana muzana yezvakaoma mune yakapihwa slurry) uye inobva yaomeswa zvachose mumoto unopisa kana muhovhoni.

Kubva paPulp muchina dhizaini, kugadzirwa kwechigadzirwa, kusvika kutengesa, kushambadzira, sevhisi, uye manejimendi, Zhiben ine pulse mukuita kwakazara.Isu tine chiyero chepamusoro chekuvimba mukugadzira michina yekugadzira.Kunze kwekubata midziyo yepamusoro, Zhiben akaisawo kutenda kwedu uye chivimbo mumutsara wedu wekugadzira pulp.Isu tinosiyana mukufunga kwedu kubva paavhareji pulp molding michina inogadzira.

Matanho ekugadzira mukugadzirwa kweThermoformed pulp zvigadzirwa:

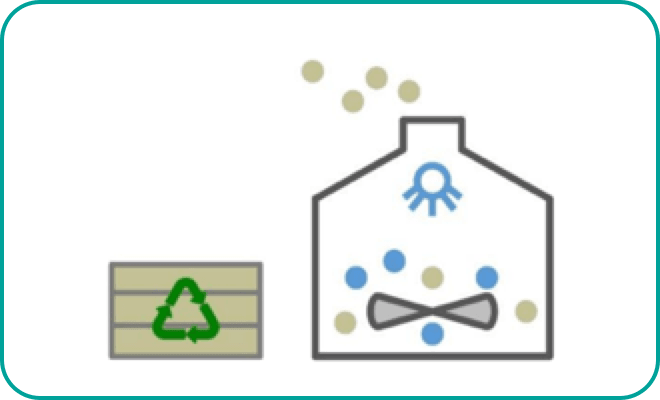

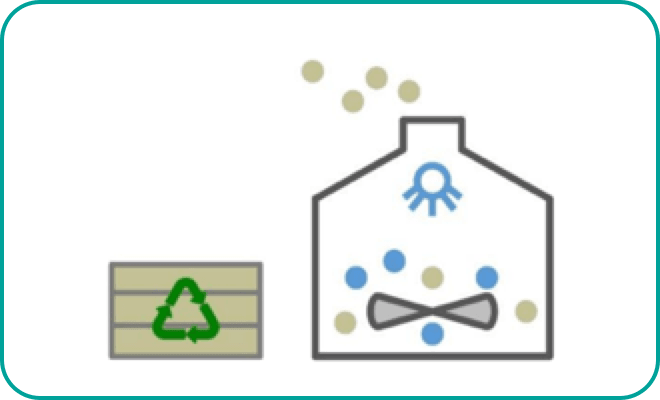

1. Pulpers inosanganisa iyo yakasvibirira, isanganise nemvura uye iyo isiri-fiber zvinhu inobviswa.

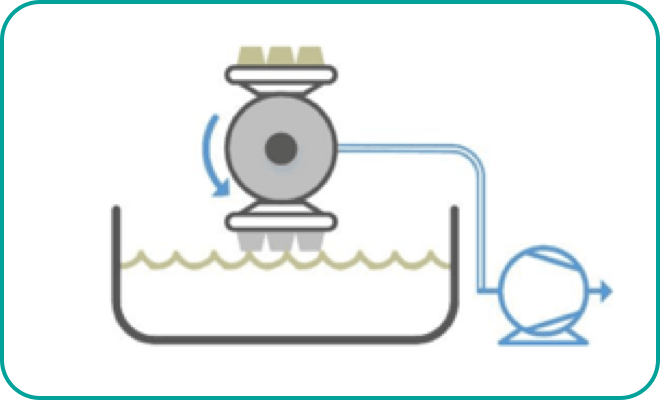

2. Michina inokwevera pulp pazviumbwa uye kubvisa mvura nekuisa vacuum kugadzira chigadzirwa.

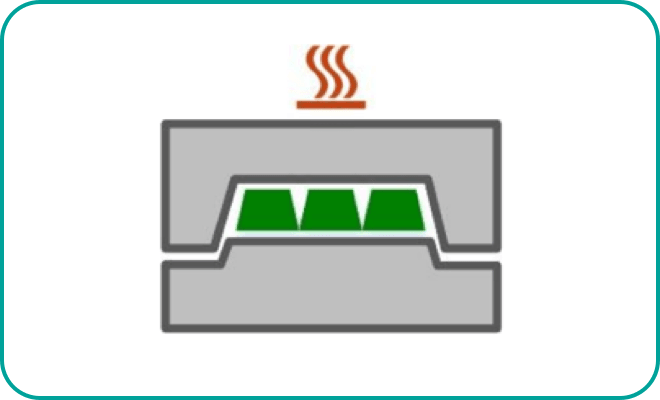

3. Chikamu chacho chinodzvinyirirwa uye chakaomeswa nemaviri anopisa anofananidzwa nehafu ye mold.

4. Zvikamu zvakapedzwa zvinoongororwa zvemhando uye zvinobva zvarongedzerwa nekuiswa pallet.